☰

Lorrain’s scramjet

Scramjet flow-field | RAS turbulence modelling

![]() Working directory located here

Working directory located here

![]() J.-J. O.E. Hoste, V. Casseau, M. Fossati, I. J. Taylor, and R. Gollan, "Numerical Modeling and Simulation of Supersonic Reacting Flows in Propulsion Systems by Open-Source Solvers," 21st AIAA International Space Planes and Hypersonic Systems and Technologies Conference (Xiamen, China, 6-9 March 2017), AIAA Paper 2017-2411, 2017 [PDF Preprint→]

J.-J. O.E. Hoste, V. Casseau, M. Fossati, I. J. Taylor, and R. Gollan, "Numerical Modeling and Simulation of Supersonic Reacting Flows in Propulsion Systems by Open-Source Solvers," 21st AIAA International Space Planes and Hypersonic Systems and Technologies Conference (Xiamen, China, 6-9 March 2017), AIAA Paper 2017-2411, 2017 [PDF Preprint→]

Stage 1 - Fuel-off

1. CASE SETUP

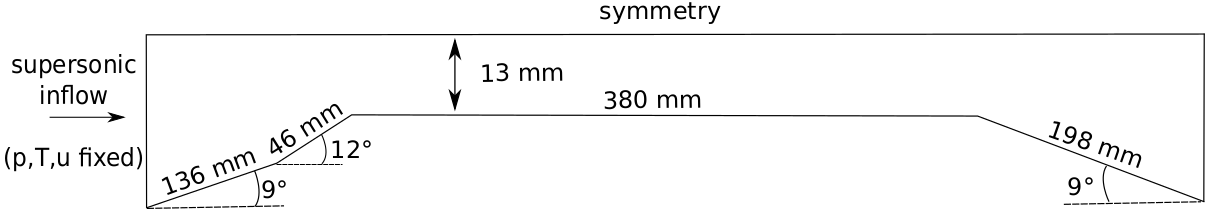

1.1 Geometry & Mesh

Lorrain’s scamjet geometry

The mesh is composed of 322080 hexahedra, and the maximum first cell distance to physical walls is less than 5 x 10-6 m ensuring that the first cell is located inside the viscous sublayer.

1.2 Case conditions

The inflow (in) conditions of the fuel-off Lorrain scramjet case are:

- Main = 7.32

- pin = 4100 Pa

- Tin = 370 K

- Uin = (2830 0 0) m/s

- XN2, in = 0.79

- XO2, in = 0.21

- XH2, in = 0.0

The no-slip isothermal walls are maintained at a temperature of 300 K.

1.3 Thermo-chemical and transport models

This test case is using the following thermo-chemical and transport models:

- thermally-perfect gas (excluding the electronic energy contribution)

- no chemical reactions

- thermal equilibrium

- species viscosity & thermal conductivity: CEA2

- mixing rule: Wilke

- no species diffusion

- turbulent model: k-omega SST

1.4 Time controls

The initial time-step is set to 1 x 10-10 s and the maximum CFL number is 0.1. The simulation end time is equal to 0.0013 s.

2. RUNNING

The following commands will copy the mesh from

./Allclean

./Allrun

To run hyFoam in parallel (say on 4 CPUs), please first edit the

./Allclean

./Allrun 4

3. FLOW VISUALISATIONS IN PARAVIEW

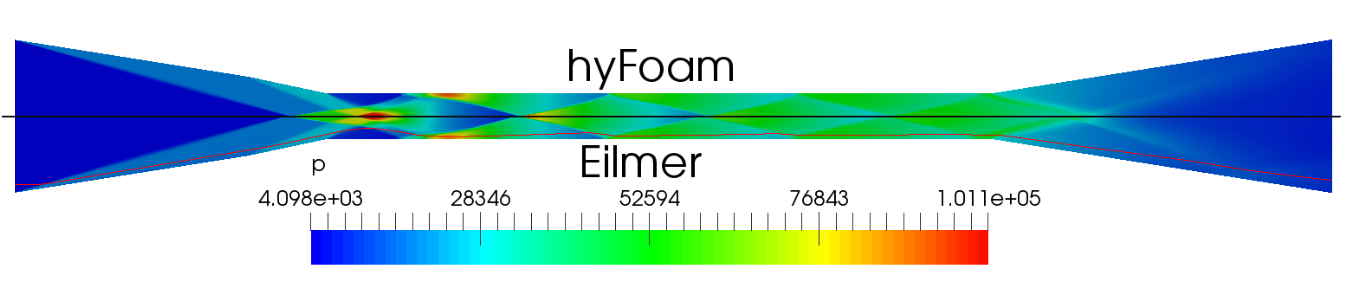

Contour plots of pressure for hyFoam and Eilmer show a similar shock structure

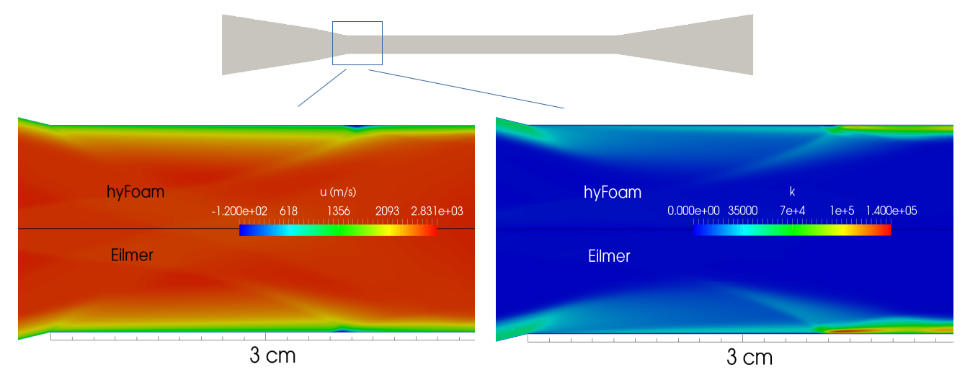

Shock induced boundary layer separation with contours of velocity and turbulent kinetic energy for both solvers

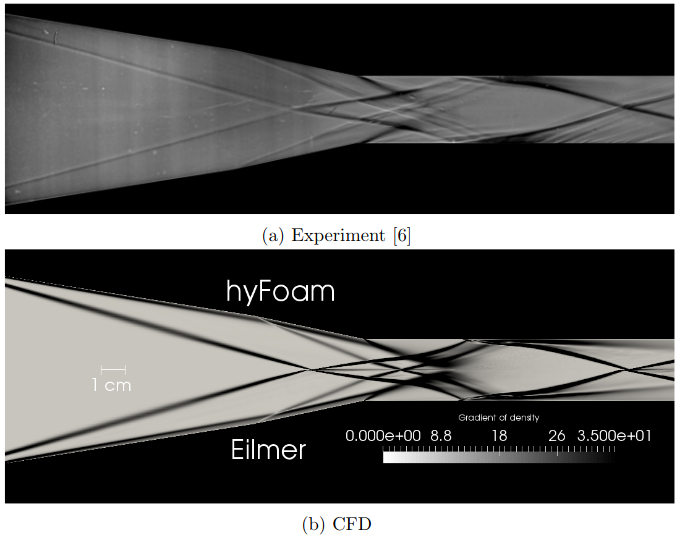

A comparison between the experimental Schlieren and CFD results (gradient of density) for the fuel-off conditions (scales do not match perfectly).

4. SOLUTION

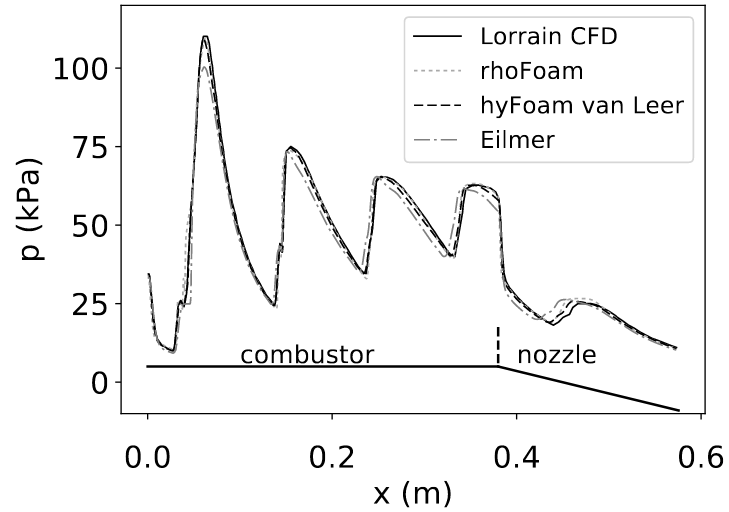

Static pressure along a streamline starting 1.5 mm from the combustor’s entrance wall

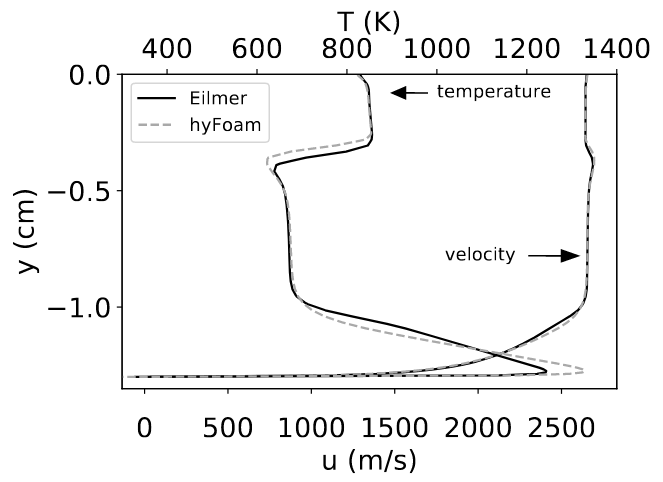

Temperature and velocity profiles at the entrance of the combustor section for Eilmer and hyFoam

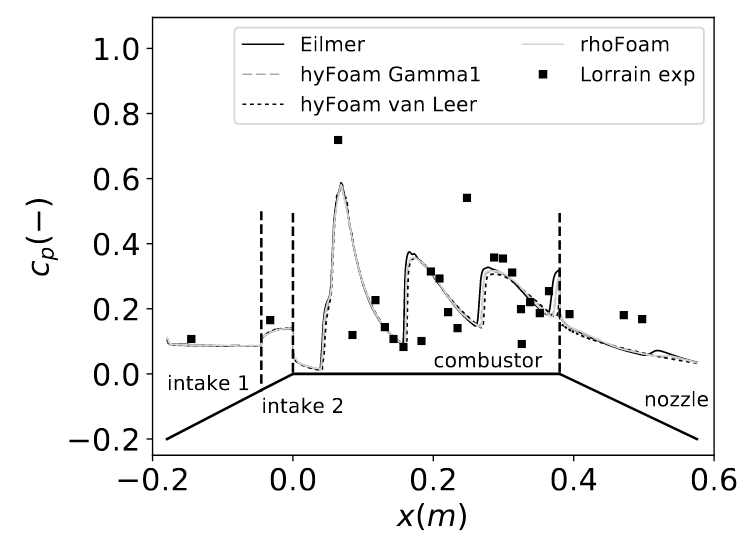

Pressure coefficient along the wall

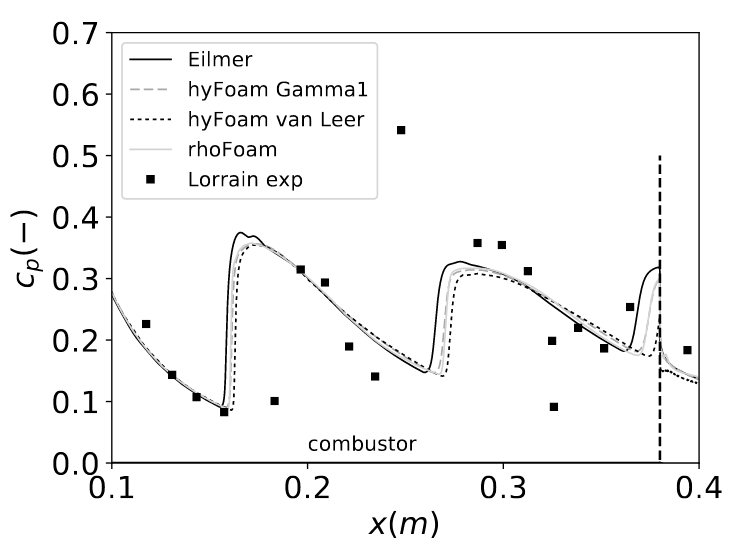

Close-up view of the pressure coefficient in the combustor section

![]() Additional references

Additional references

Eilmer3 is a research and educational simulation code for 2D and 3D gas dynamics designed by Dr Peter Jacobs, Dr Rowan Gollan, Dr Daniel Potter and others (University of Queensland, Australia) [Eilmer3 Website→]

Eilmer3, Eilmer4 | J.-J. O.E. Hoste, "Scramjet Combustion Modeling using Eddy Dissipation Model," PhD thesis, University of Strathclyde, Glasgow (UK), 2018 [PDF→]

rhoCentralFoam, Eilmer3, hyFoam | D. Puorto, "Suitability of rhoCentralFoam for Scramjet Internal Flows," Master's thesis, University of Naples Federico II, Naples (Italy), 2017

Contributors: Dr Jimmy-John O.E. Hoste, Daniela Puorto, Dr Vincent Casseau